Providing Convenient Bus and Rail Service to the Denver Metro Area

Our ServicesGet where you want to go with over 100 Local, Regional and SkyRide bus routes, 10 rail lines providing 113 miles of rail service and 96 Park-n-Rides.

Routes and Services

Board of DirectorsRTD is governed by a 15-member, publicly elected Board of Directors. Directors are elected to a four-year term and represent a specific district. Interactive District Map

Now HiringMove Your City - Apply today to become a Bus Operator or Train Operator. RTD offers opportunity, stability, and on-the-job training.Careers

Transit WatchLocal communities and citizens play an important role in keeping our transit system safe. Use our app to report an issue.Transit Watch

RTD’s downtown light rail reconstruction project

May 2024

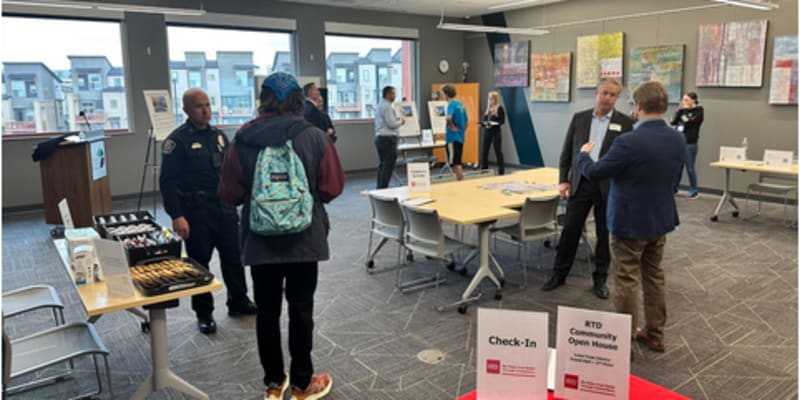

After more than 30 years, RTD is investing in its oldest rail infrastructure to ensure the long-term integrity of the network. The near-term work will occur in four phases, with the first phase commencing in May 2024, focusing on five segments of track at street intersections in the Downtown Loop. Phases two through four of the approximately $152 million-dollar, full-depth reconstruction project will occur in 2025.

Learn MoreEvents

News Stop

★ ★ ★ ★ ★ Hiring veterans like you.

Some positions eligible for $4,000 signing bonus.

RTD values the service and skills developed during your military experience. Qualities like determination, team building, leadership and confidence will allow you to make a difference in your community as a member of our team.

Apply Now